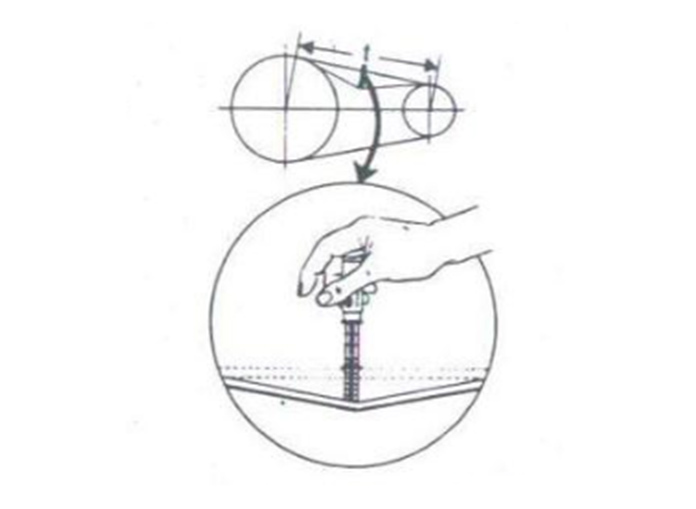

- Measures the Span Length(t)

- Position the lower of the two O-rings using either of the following methods:

- On the scale of reading “ Deflection Inches,” Set the O-ring to show a deflection equal to 1/64” per inch of span length(t).

- On the scale reading “ inches of Span Length,” set the O-ring to show a deflection equal to the inches of measures span length(t) Read scales at the bottom edge of O-ring. Leave the upper O-ring in maximum up position.

- At center of span(t) apply force, with Gates Tension Tester Perpendicular to the span, large enough to deflect one belt on the drive until the bottom edge of the lower O-ring is even with the tops of the remaining belts. A straight edge across the belt tops will insure accuracy of positioning.

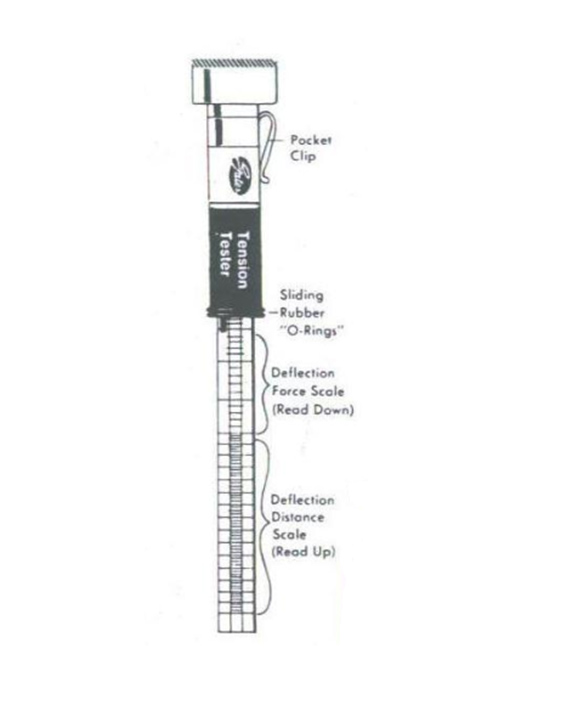

- Find amount of deflection force on upper scale of Tension Tester. The sliding Rubber “O-ring” slides down scale as tool compresses — stays down for accurate reading of pounds presser. Read at top edge of ring. ( slide ring up before re-using)

- Compare deflection force with range of forces in tables below. If less than minimum recommended deflection force belts should be tightened. If more than maximum recommended deflection force. Drive is tighter than necessary.

- Call us: +91 (0)22 4343 4444 |

- info@beltingenterprises.in

Single Tension Tester

How to Tension Multiple V Belt Drives

With Your Gates Tension Tester

RECOMMENDED DEFLECTION FORCE PER BELT

(For Hi-Power II V-Belts & Power Band and Tri-power V-Belts)

| V Belt Cross Sections | Small Sheaves Diameter Range ( inches) | Small Sheaves RPM Range | Speed ratio range | Recommended deflection Force ( Pounds) | |||

|---|---|---|---|---|---|---|---|

| Hi-Power II & Power Band | Tri - Power | ||||||

| Min | Max | Min | Max | ||||

| A | 3.0 | 1750

To 3600 |

2.0

To 4.0 |

2.7 | 3.8 | 3.8 | 5.4 |

| 3.2 | 2.9 | 4.2 | 3.9 | 5.6 | |||

| 3.4 - 3.6 | 3.3 | 4.8 | 4.1 | 5.9 | |||

| 3.8 - 4. 2 | 3.8 | 5.5 | 4.3 | 6.3 | |||

| 4.6 - 7.0 | 4.9 | 7.1 | 4.9 | 7.1 | |||

| B | 4.6 | 1160

To 1800 |

2.0

To 4.0 |

5.1 | 7.4 | 7.1 | 10 |

| 5.0 – 5.2 | 5.8 | 8.5 | 7.3 | 11 | |||

| 5.4 – 5.6 | 6.2 | 9.1 | 7.4 | 11 | |||

| 6.0 – 6.8 | 7.1 | 10 | 7.7 | 11 | |||

| 7.4 – 9.4 | 8.1 | 12 | 7.9 | 12 | |||

| C | 7.0 | 870

To 1800 |

2.0

To 4.0 |

9.1 | 13 | 12 | 18 |

| 7.5 | 9.7 | 14 | 12 | 18 | |||

| 8.0 – 8.5 | 11 | 16 | 13 | 18 | |||

| 9.0 – 10.5 | 12 | 18 | 13 | 19 | |||

| 11.0 – 16.0 | 14 | 21 | 13 | 19 | |||

| D | 12.0 – 13.0 | 690 To 1200 |

2.0 To 4.0 |

19 | 27 | 19 | 28 |

| 13.5 – 15.5 | 21 | 30 | 21 | 31 | |||

| 16.0 – 22.0 | 24 | 36 | 25 | 36 | |||

| E | 21.6 – 24.0 | 435

To 900 |

2.0

To 4.0 |

32 | 47 | ||

Note : There will normally be a rapid drop in tension during the “run – in period” , Tension new drives with a 1/3 greater deflection force than the maximum force recommended. Check tension frequency during the first day of operation.

Recommended Deflection Force Per Belt

For Super HC* V-Belts, Super HC PowerBand * Belts,

Super HC Molded Notch V-Belt or

Super HC Molded Notch Power Band Belts

| V- Belt Cross Section | Small Sheave Diameter Range ( Inches) | Small Sheave RPM Range | Speed Ration Range | Recommended Deflection Force ( Pounds ) | |

|---|---|---|---|---|---|

| Minimum | Maximum | ||||

| 3VX | 2.20 | 1200 – 3600 | 2.0

To 4.0 |

2.8 | 4.1 |

| 2.35 – 2.50 | 1200 – 3600 | 3.2 | 4.7 | ||

| 2.65 – 2.80 | 1200 – 3600 | 3.5 | 5.1 | ||

| 3.00 - 3.15 | 1200 – 3600 | 3.8 | 5.5 | ||

| 3.35 – 3.65 | 1200 – 3600 | 4.1 | 6.0 | ||

| 4.12 – 5.00 | 900 – 3600 | 4.8 | 7.1 | ||

| 5.30 – 6.90 | 900 – 3600 | 5.8 | 8.6 | ||

| 5VX | 4.40 – 4.65 | 1200 - 3600 | 2.0

To 4.0 |

9.0 | 13 |

| 4.90 – 5.50 | 1200 - 3600 | 10 | 15 | ||

| 5.90 – 6.70 | 1200 - 3600 | 11 | 17 | ||

| 7.10 – 8.00 | 600 - 1800 | 13 | 19 | ||

| 8.50 – 10.90 | 600 - 1800 | 14 | 20 | ||

| 11.80 – 16.00 | 400 - 1200 | 15 | 23 | ||

| C | 7.10 – 8.00 | 600 - 1800 | 2.0

To 4.0 |

11 | 16 |

| 8.50 – 10.90 | 600 - 1800 | 13 | 18 | ||

| 11.80 – 16.00 | 400 – 1200 | 14 | 21 | ||

| 8V | 12.50 – 17.00 | 600 – 1200 | 2.0 To 4.0 |

28 | 41 |

| 18.00 – 24.00 | 400 – 900 | 32 | 48 | ||

*If replacing 3V or 5V belts with the same belt length and same number of belts in 3VX & 5VX cross section, Belt tension does not need to be increased.

Note : New Drives designed with 3VX or 5VX belts Should be tensioned at the respective deflection force value shown in the above table.